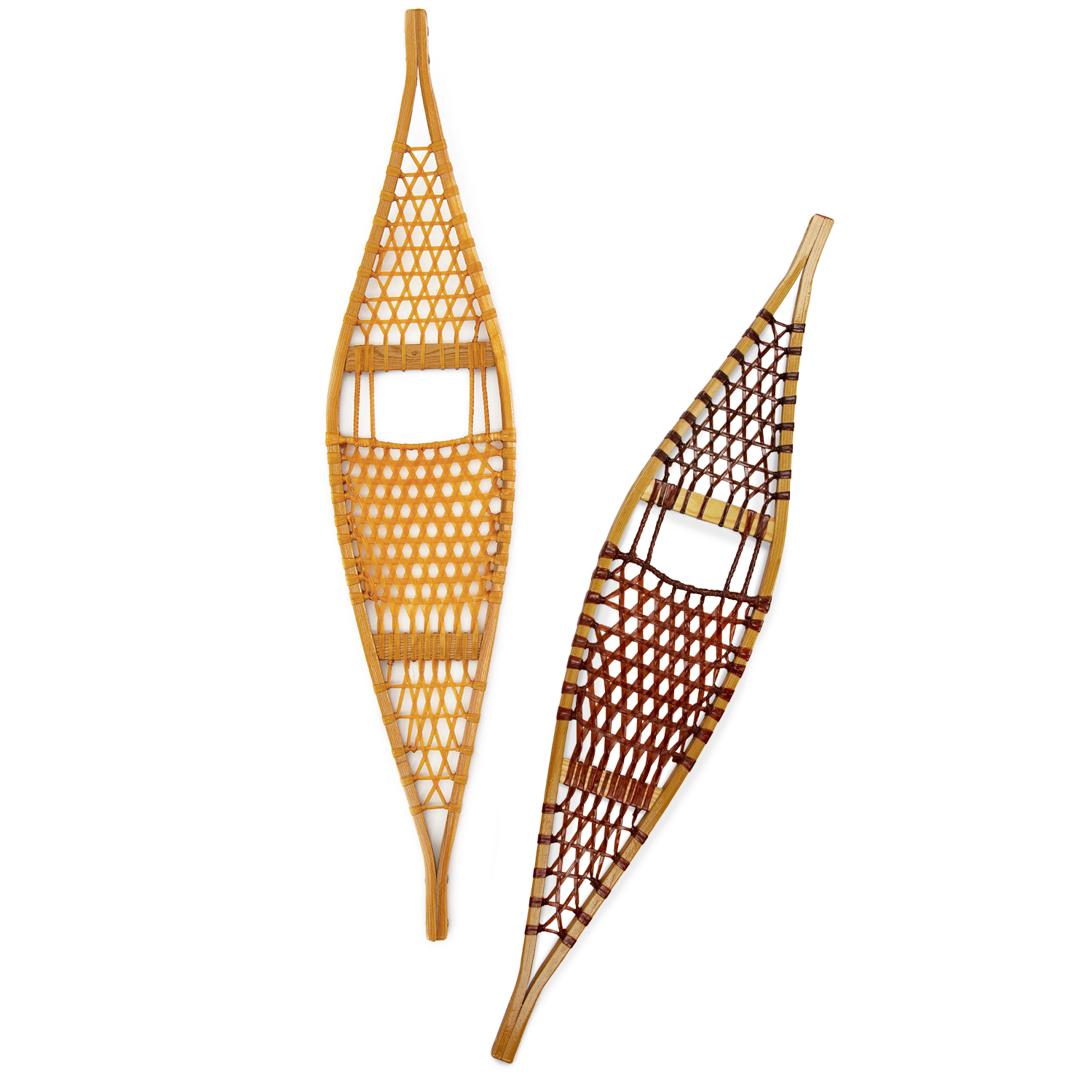

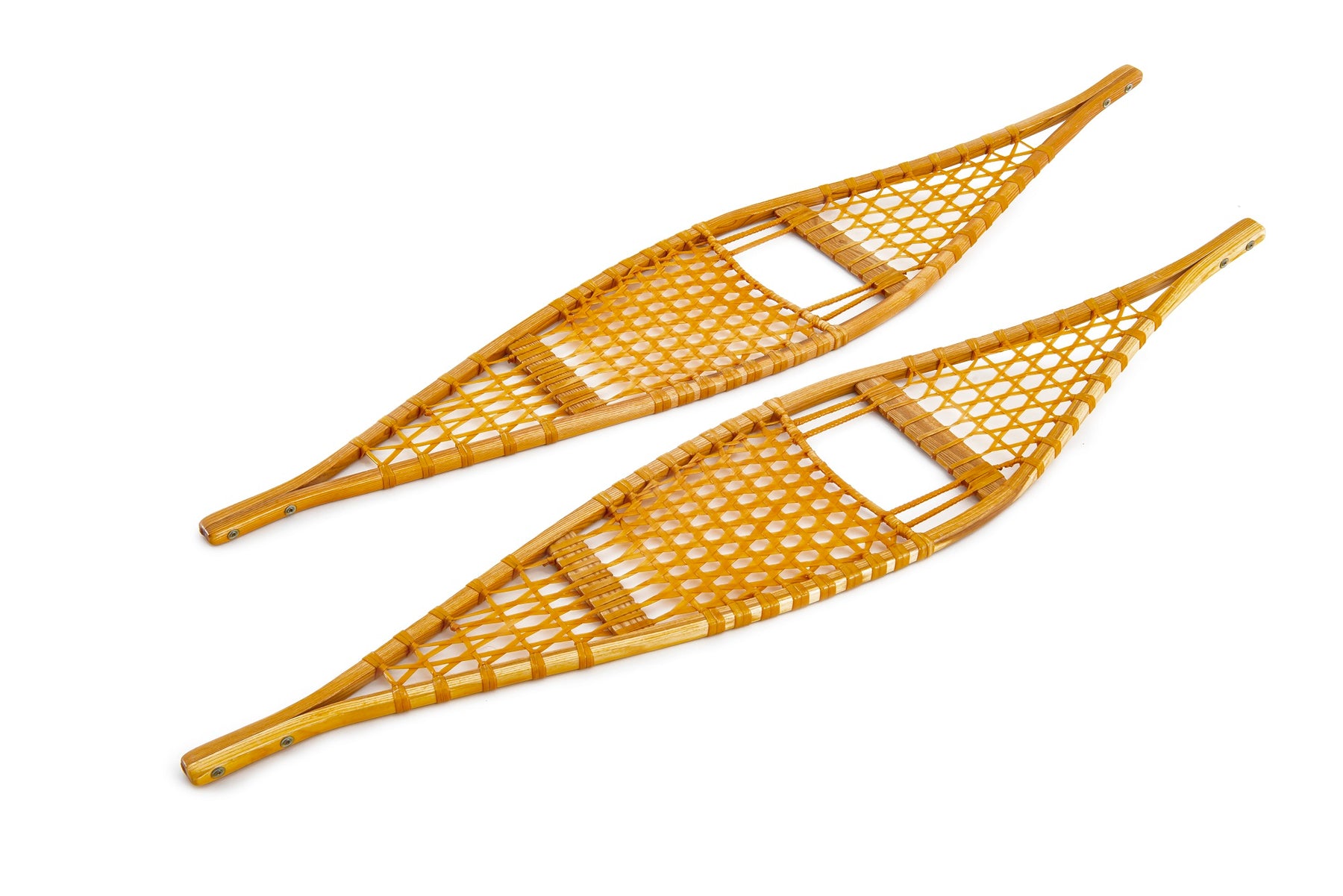

Northern Snowshoe

Ojibwa Finished Snowshoes

Shipping & Wholesale

Free domestic shipping on large products to all residents of the lower 48 states. Small products ship USPS for a flat $9 rate. International shipping has additional fees.

WholesaleInterested in wholesale opportunites? Contact Us!

Ojibwa Snowshoe Sizing

Roughly match snowshoe size to your body weight plus the weight of any pack.

As a rule, smaller shoes are easier to walk on. If close to a size break, choose larger shoes if you have long legs, wear a hefty pack, regularly break trail or have light, fluffy snow.

Choose smaller shoes for shorter legs, denser snow or packed trails (even if new snow covers the old tracks).

|

For Ojibwa Models

|

|||

|

Model

|

Dimensions

|

Age / Weight

|

Surface Floatation Area

|

|

YOUTH

|

9" x 36"

|

Age 6 to about 120#

|

320 Sq. in.

|

|

SMALL

|

10" x 48"

|

Age 8 to about 140#

|

510 sq. in.

|

|

MEDIUM

|

11" x 54"

|

130# to about 240#

|

645 sq. in.

|

|

LARGE

|

12" x 60"

|

6'tall and 210# and up

|

700 sq. in.

|

Choose options

Shipping & Wholesale

Free domestic shipping on large products to all residents of the lower 48 states. Small products ship USPS for a flat $9 rate. International shipping has additional fees.

WholesaleInterested in wholesale opportunites? Contact Us!

Shipping & Wholesale

Free domestic shipping on large products to all residents of the lower 48 states. Small products ship USPS for a flat $9 rate. International shipping has additional fees.

WholesaleInterested in wholesale opportunites? Contact Us!

Explore the Ojibwa Finished Snowshoes Features